Vav box with reheat coil – VAV boxes with reheat coils play a pivotal role in modern HVAC systems, delivering exceptional comfort and energy savings. These devices precisely control airflow and temperature, creating optimal indoor environments while minimizing energy consumption.

Their versatility and adaptability make VAV boxes with reheat coils ideal for various applications, from commercial buildings to industrial facilities. This comprehensive guide delves into the intricacies of these innovative HVAC components, exploring their types, benefits, design considerations, installation, and maintenance.

VAV Box with Reheat Coil Overview

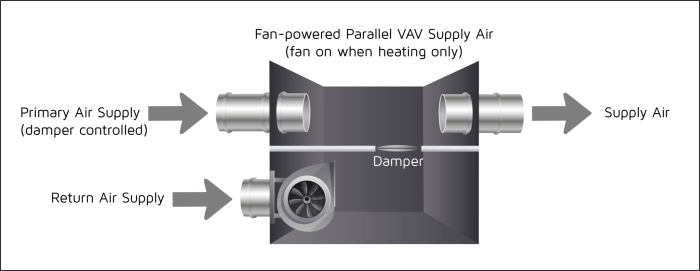

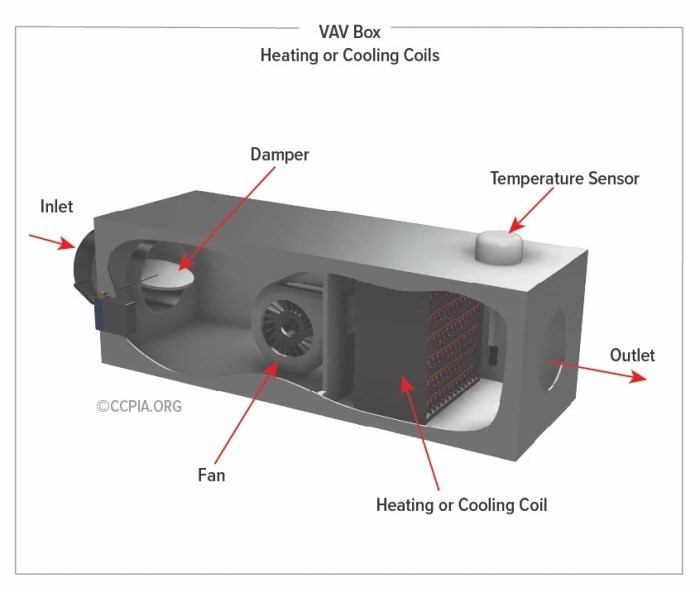

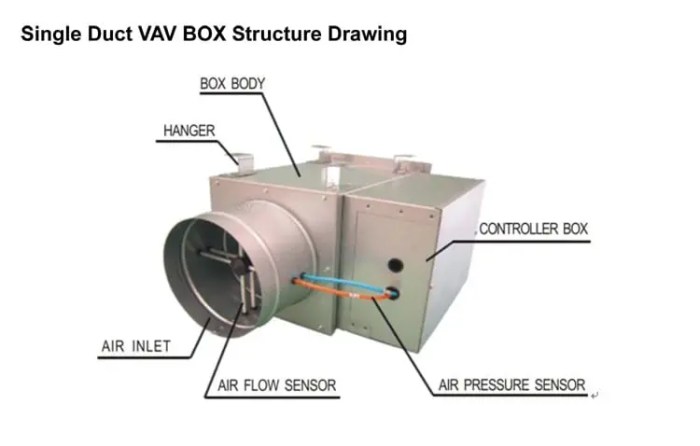

A VAV (Variable Air Volume) box with a reheat coil is a device used in HVAC (Heating, Ventilation, and Air Conditioning) systems to control the temperature and airflow in a specific zone or space. It consists of several components, including a damper, reheat coil, and controls.

Purpose and Functionality

The primary purpose of a VAV box with a reheat coil is to maintain a desired temperature in a zone while also providing precise control over the airflow. The damper regulates the amount of air flowing into the zone, while the reheat coil adds heat to the air if needed to maintain the desired temperature.

This combination of airflow control and temperature adjustment allows for efficient and precise temperature management in various applications.

Types of VAV Boxes with Reheat Coils

VAV boxes with reheat coils come in various types, each with distinct features and applications. The following table provides an overview of the different types:

| Type | Features | Applications |

|---|---|---|

| Constant Volume (CV) | Fixed airflow rate, no modulation | Applications requiring constant airflow, such as cleanrooms and laboratories |

| Variable Air Volume (VAV) | Modulating airflow rate, maintains constant temperature | Widely used in commercial and industrial buildings for efficient temperature control |

| Dual Duct | Mixing of hot and cold air to achieve desired temperature | Suitable for applications where both heating and cooling are required simultaneously |

| Bypass | Airflow bypasses the reheat coil, providing cooling or ventilation | Used in applications where additional cooling is required, such as data centers |

Benefits of Using VAV Boxes with Reheat Coils

VAV boxes with reheat coils offer numerous advantages in terms of energy efficiency, comfort, and control within HVAC systems. These benefits make them a popular choice for various applications, including commercial buildings, healthcare facilities, and educational institutions.

Energy Efficiency

- Reduced energy consumption: VAV boxes with reheat coils allow for precise control of airflow, ensuring that only the necessary amount of conditioned air is supplied to each zone. This reduces energy waste and lowers operating costs.

- Optimized heating and cooling: Reheat coils provide additional heating capacity, enabling the system to maintain desired temperatures even when the primary heating or cooling source is not operating at full capacity. This results in more efficient use of energy.

Improved Comfort

- Enhanced temperature control: Reheat coils allow for precise temperature control within each zone, eliminating hot or cold spots and ensuring a comfortable environment for occupants.

- Reduced drafts and stratification: VAV boxes with reheat coils help to minimize drafts and temperature stratification, creating a more uniform and comfortable indoor environment.

Enhanced Control

- Flexibility and adaptability: VAV boxes with reheat coils provide flexibility in system design and operation. They can be easily integrated into existing HVAC systems and adjusted to meet changing occupancy and environmental conditions.

- Improved indoor air quality: Reheat coils can be equipped with filtration systems to improve indoor air quality by removing pollutants and allergens from the air.

Design Considerations for VAV Boxes with Reheat Coils

Designing VAV boxes with reheat coils requires careful consideration of several factors to ensure optimal performance and efficiency.

These factors include airflow requirements, pressure drop, and coil selection, which must be carefully balanced to meet the specific needs of the application.

Airflow Requirements, Vav box with reheat coil

The airflow requirements of the VAV box determine the size and capacity of the reheat coil. The airflow rate must be sufficient to meet the heating or cooling load of the zone served by the VAV box, while also ensuring that the air velocity through the coil is within acceptable limits.

Vav boxes with reheat coils, essential components in various industries, share a linguistic connection with words that end in cion , such as “narration” and “complication.” These terms encompass a sense of gradual progression or a culmination of events, reflecting the sequential processes involved in the operation of vav boxes with reheat coils.

Pressure Drop

The pressure drop across the VAV box and reheat coil must be considered to ensure that the system can deliver the required airflow rate. Excessive pressure drop can lead to reduced airflow and poor performance. The pressure drop through the VAV box and coil should be carefully calculated and accounted for in the system design.

Coil Selection

The selection of the reheat coil is critical to the performance of the VAV box. The coil must be sized to provide the required heating or cooling capacity, and the coil type (e.g., hot water, steam, or electric) must be compatible with the system design.

Installation and Maintenance of VAV Boxes with Reheat Coils

Installing and maintaining VAV boxes with reheat coils requires meticulous attention to detail to ensure optimal performance and longevity. This section provides a step-by-step guide to assist with the installation and maintenance processes.

Installation

1.

-

-*Site Preparation

Determine the appropriate location for the VAV box and ensure adequate space for access and maintenance.

- 2.

- 3.

- 4.

- 5.

-*Mounting

Securely mount the VAV box according to the manufacturer’s specifications. Use vibration-isolating mounts if necessary.

-*Ductwork Connection

Connect the VAV box to the supply and return air ducts using flexible or rigid ductwork. Ensure airtight connections.

-*Electrical Connections

Connect the VAV box to the power supply and control system. Verify the wiring is correct and secure.

-*Calibration

Calibrate the VAV box according to the manufacturer’s instructions to ensure accurate airflow measurement and control.

Maintenance

1.

-

-*Regular Inspections

Periodically inspect the VAV box for any signs of damage or wear. Check for loose connections, leaks, or obstructions.

- 2.

- 3.

- 4.

- 5.

-*Filter Replacement

Replace the filter regularly to prevent dust and debris from accumulating and affecting airflow.

-*Coil Cleaning

Clean the reheat coil regularly to remove dirt and debris that can reduce heat transfer efficiency.

-*Damper Operation

Check the operation of the damper to ensure it opens and closes smoothly and without binding.

-*Sensor Calibration

Recalibrate the sensors periodically to ensure accurate temperature and humidity readings.

Applications of VAV Boxes with Reheat Coils: Vav Box With Reheat Coil

VAV boxes with reheat coils offer versatility in temperature control for various industries and building types. Here’s a table showcasing their diverse applications:

| Industry | Building Type | Specific Uses |

|---|---|---|

| Healthcare | Hospitals, clinics | Patient rooms, operating rooms, recovery areas |

| Education | Schools, universities | Classrooms, lecture halls, laboratories |

| Commercial | Offices, retail stores | Open-plan offices, meeting rooms, sales floors |

| Industrial | Manufacturing plants, warehouses | Production areas, storage facilities, loading docks |

| Hospitality | Hotels, restaurants | Guest rooms, dining areas, conference halls |

Troubleshooting VAV Boxes with Reheat Coils

Troubleshooting VAV boxes with reheat coils involves identifying and resolving common problems to ensure optimal performance and comfort.

Common Problems and Troubleshooting Steps

Some common problems associated with VAV boxes with reheat coils include:

-*Insufficient airflow

Check if the VAV box damper is fully open.

Inspect the ductwork for blockages or leaks.

- Ensure the fan is operating at the correct speed.

-*Excessive noise

Check if the reheat coil is properly secured.

Inspect the fan for any imbalances or loose parts.

- Adjust the airflow to reduce turbulence.

-*Overheating or underheating

Verify the temperature sensor calibration.

Check the reheat coil for any fouling or scaling.

- Adjust the temperature setpoint or control algorithm.

-*Condensation

Inspect the insulation around the reheat coil.

Check if the condensate drain is clear and not blocked.

- Increase the airflow rate to reduce humidity levels.

-*Electrical faults

Check the power supply to the VAV box and reheat coil.

Inspect the wiring for any loose connections or damage.

Use a multimeter to test the continuity of the electrical components.

Future Trends in VAV Boxes with Reheat Coils

The future of VAV boxes with reheat coils holds exciting advancements in energy efficiency, connectivity, and maintenance.

Energy-Efficient Designs

Emerging technologies like variable-speed drives (VSDs) and advanced control algorithms will enhance energy efficiency by optimizing airflow and reheat coil operation. These advancements will reduce energy consumption, lower operating costs, and contribute to sustainability goals.

IoT Integration

Integration with the Internet of Things (IoT) will enable remote monitoring, data analysis, and predictive maintenance. Sensors and actuators will provide real-time insights into VAV box performance, allowing for proactive maintenance and reduced downtime.

Predictive Maintenance

Machine learning algorithms will analyze operational data to predict potential issues and optimize maintenance schedules. This proactive approach will minimize disruptions, extend equipment life, and ensure optimal performance.

Expert Answers

What is a VAV box with a reheat coil?

A VAV box with a reheat coil is a device that controls the airflow and temperature in an HVAC system. It uses a variable air volume (VAV) damper to adjust the airflow, and a reheat coil to heat the air as needed.

What are the benefits of using VAV boxes with reheat coils?

VAV boxes with reheat coils offer several benefits, including energy efficiency, improved comfort, and enhanced control over the indoor environment.

How are VAV boxes with reheat coils installed and maintained?

Installing and maintaining VAV boxes with reheat coils requires specialized knowledge and skills. It is recommended to consult with a qualified HVAC technician for proper installation and regular maintenance.